Technology

Extrusion Coating Machines

The Extrusion Coating Machine is a specialized piece of industrial equipment utilized in the manufacturing process to apply a thin layer of plastic material onto a substrate, commonly consisting of paper, cardboard, or films, with the aim of enhancing its properties and performance. The machine operates through the extrusion process, whereby a molten polymer is compelled through a die to generate a continuous layer onto the substrate.

• Material Melting

• Extrusion

• Laminating

• Cooling and Solidification

• Trimming and Cutting

Roto-Gravure Printing Machines

A Rotogravure Printing Machine is a specialized printing equipment used to produce high-quality, continuous-tone images on various flexible materials. The machine employs a gravure printing process, where an image is engraved onto a cylindrical printing plate, and the ink is transferred from the recessed cells of the plate onto the substrate.

• Cylinder Prepration

• Ink Application

• Doctor Blade

• Printing

• Drying

Lamination Machines

A Solvent-Based Lamination Machine is an industrial equipment used for applying a protective layer onto printed materials or substrates using solvent-based adhesives. This process enhances the appearance, durability, and sometimes functionality of the substrate. The machine employs a solvent-based adhesive to bond the protective layer onto the surface of the substrate.

• Preparation

• Adhesive Application

• Laminating

• Evaporation

• Trimming and Cutting

Slitting and Inspection Machines

The Extrusion Coating Machine is a specialized piece of industrial equipment utilized in the manufacturing process to apply a thin layer of plastic material onto a substrate, commonly consisting of paper, cardboard, or films, with the aim of enhancing its properties and performance. The machine operates through the extrusion process, whereby a molten polymer is compelled through a die to generate a continuous layer onto the substrate.

• Unwinding

• Slitting

• Tension Control

• Inspection

• Rewinding

• Finished Product

Lamination Machines

A Solvent-Based Lamination Machine is an industrial equipment used for applying a protective layer onto printed materials or substrates using solvent-based adhesives. This process enhances the appearance, durability, and sometimes functionality of the substrate. The machine employs a solvent-based adhesive to bond the protective layer onto the surface of the substrate.

• Preparation

• Adhesive Application

• Laminating

• Evaporation

• Trimming and Cutting

Pouching Machines

A Pouching Machine is a specialized industrial equipment designed to manufacture and seal pouches or bags from flexible materials, such as plastic films or laminates. This machine plays a crucial role in packaging various products securely and efficiently. The Pouching Machine is an essential tool for creating and sealing pouches from flexible materials. Its mechanism involves forming, filling, sealing, and cutting to produce secure and convenient packaging for a wide range of products. The machine’s versatility makes it a valuable asset in industries ranging from food and pharmaceuticals to cosmetics and beyond, ensuring efficient packaging and product protection.

• Material Unwinding

• Forming the Pouch

• Die Cutting

• Sealing

• Cutting

• Output

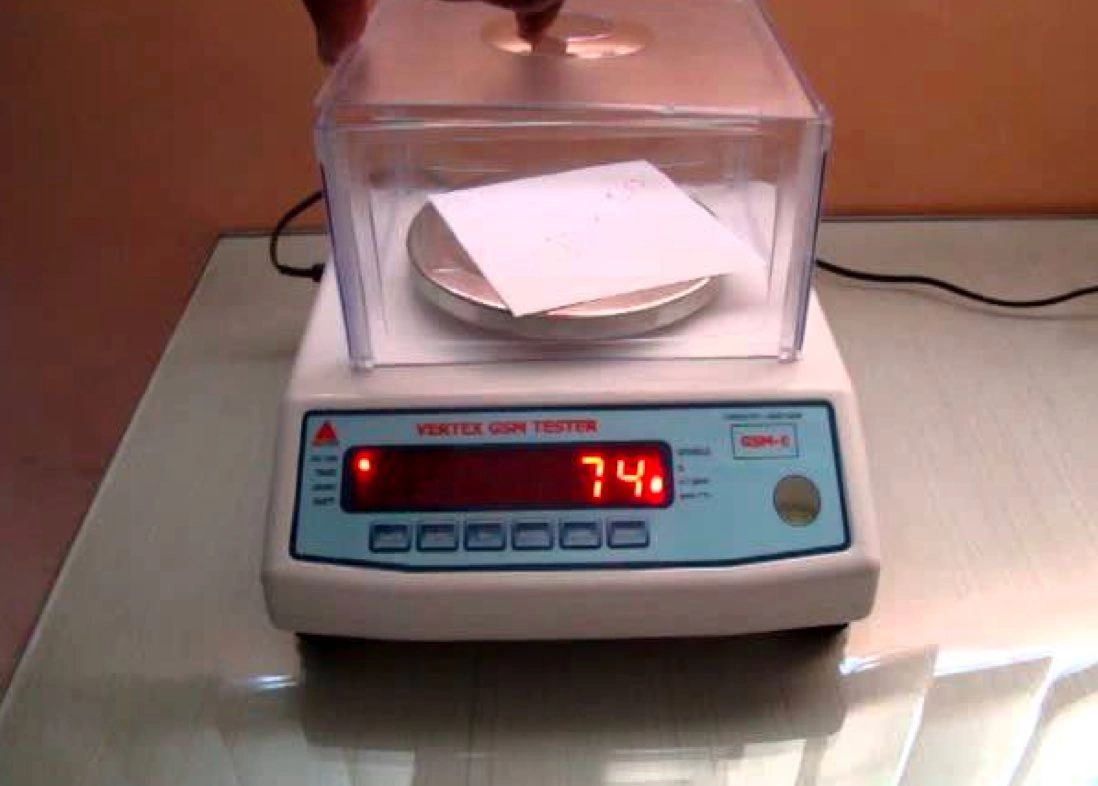

Quality Checking Machines

Quality machines like the GSM Tester Machine is an essential instruments for industries dealing with materials like paper, paperboard, textiles, and non-woven fabrics. Its mechanism involves accurately weighing a sample and calculating the grammage, providing valuable information for quality control and adherence to industry standards. These machines are indispensable tools in ensuring the reliability and consistency of materials used in various applications.

• Sampling Preparation

• Weighing the Sample

• Calculation